- 메일 주소 : David@tmaxcn.com

- 메일 주소 : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

리튬 배터리 실험실 기계

Enhancing Battery Production Efficiency with Prismatic Cell Manufacturing Equipment

August 11,2023.

Enhancing Battery Production Efficiency with Prismatic Cell Manufacturing Equipment

Introduction:

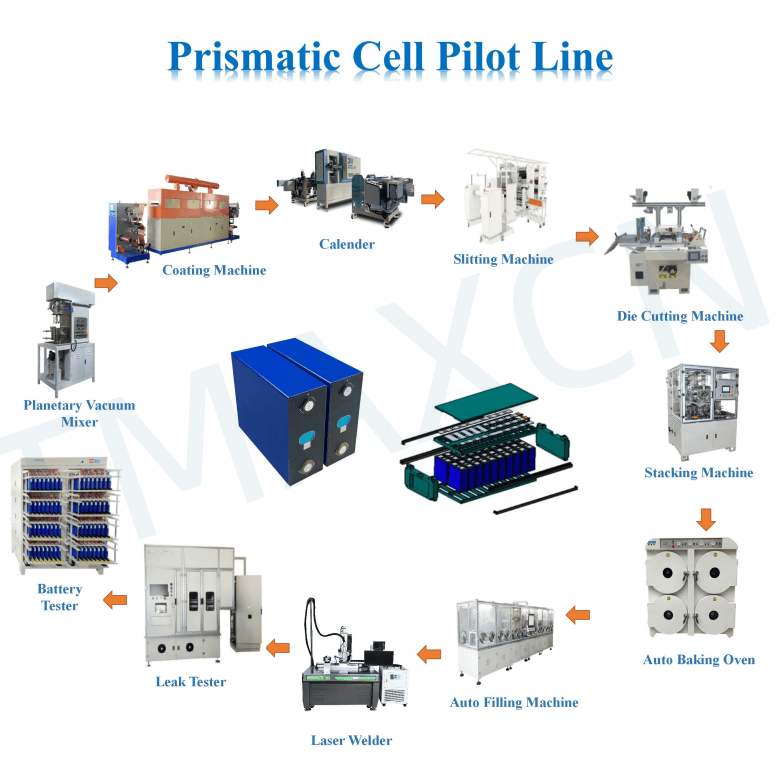

Prismatic cell manufacturing equipment plays a crucial role in the battery production process, enabling manufacturers to achieve higher efficiency, consistency, and quality in the production of prismatic battery cells. As the demand for energy storage solutions continues to grow, the significance of efficient battery manufacturing equipment becomes even more evident. In this article, we will delve into the key features and benefits of prismatic cell manufacturing equipment, shedding light on how it contributes to streamlined battery production.

Streamlined Production Process:

Prismatic cell manufacturing equipment is designed to optimize the production process by automating various stages, from electrode coating machine and cell stacking to sealing and battery testing machine. Automated equipment ensures precise and consistent application of materials, reducing human error and minimizing production variations. This leads to a more efficient production line with higher throughput and reduced manufacturing costs.

Quality and Consistency:

One of the primary advantages of using prismatic cell manufacturing equipment is the ability to maintain a high level of product quality and consistency. The equipment's precision-controlled processes ensure that each prismatic cell meets the required specifications in terms of capacity, voltage, and cycle life. Manufacturers can confidently deliver reliable battery solutions that meet customer expectations and industry standards.

Innovative Design Features:

Prismatic cell manufacturing equipment often incorporates innovative design features that enhance its performance. These may include advanced robotics, real-time monitoring systems, and adaptive process controls. These features not only improve production efficiency but also enable manufacturers to quickly identify and address any potential production issues.

Cost Efficiency and Sustainability:

Investing in high-quality prismatic cell manufacturing equipment may require an initial investment, but the long-term benefits are substantial. The enhanced production efficiency and reduced scrap rates lead to significant cost savings over time. Additionally, efficient manufacturing processes contribute to sustainability efforts by minimizing waste and energy consumption.

Conclusion:

In the rapidly evolving landscape of energy storage, prismatic cell manufacturing equipment stands as a critical tool for battery manufacturers striving to meet growing demand while maintaining the highest levels of efficiency and quality. By automating processes, ensuring consistency, and incorporating innovative design features, this equipment plays a pivotal role in shaping the future of battery production.

Introduction:

Prismatic cell manufacturing equipment plays a crucial role in the battery production process, enabling manufacturers to achieve higher efficiency, consistency, and quality in the production of prismatic battery cells. As the demand for energy storage solutions continues to grow, the significance of efficient battery manufacturing equipment becomes even more evident. In this article, we will delve into the key features and benefits of prismatic cell manufacturing equipment, shedding light on how it contributes to streamlined battery production.

Streamlined Production Process:

Prismatic cell manufacturing equipment is designed to optimize the production process by automating various stages, from electrode coating machine and cell stacking to sealing and battery testing machine. Automated equipment ensures precise and consistent application of materials, reducing human error and minimizing production variations. This leads to a more efficient production line with higher throughput and reduced manufacturing costs.

Quality and Consistency:

One of the primary advantages of using prismatic cell manufacturing equipment is the ability to maintain a high level of product quality and consistency. The equipment's precision-controlled processes ensure that each prismatic cell meets the required specifications in terms of capacity, voltage, and cycle life. Manufacturers can confidently deliver reliable battery solutions that meet customer expectations and industry standards.

Innovative Design Features:

Prismatic cell manufacturing equipment often incorporates innovative design features that enhance its performance. These may include advanced robotics, real-time monitoring systems, and adaptive process controls. These features not only improve production efficiency but also enable manufacturers to quickly identify and address any potential production issues.

Cost Efficiency and Sustainability:

Investing in high-quality prismatic cell manufacturing equipment may require an initial investment, but the long-term benefits are substantial. The enhanced production efficiency and reduced scrap rates lead to significant cost savings over time. Additionally, efficient manufacturing processes contribute to sustainability efforts by minimizing waste and energy consumption.

Conclusion:

In the rapidly evolving landscape of energy storage, prismatic cell manufacturing equipment stands as a critical tool for battery manufacturers striving to meet growing demand while maintaining the highest levels of efficiency and quality. By automating processes, ensuring consistency, and incorporating innovative design features, this equipment plays a pivotal role in shaping the future of battery production.

As the industry continues to advance, the integration of advanced prismatic cell manufacturing equipment will likely lead to further improvements in battery technology and energy storage solutions, ultimately benefiting industries and consumers worldwide.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com